Protective relay testing

In every electrical device there is a complete circuit or we can say a series of inputs which contribute to the final output. In a circuit, the switch which is connected to the normal open part of a coil to make the bulb glow is called a Relay. A relay is an electro-mechanical and an electro-magnetic switch which uses electro magnetism, as clear from the definition, received by it from a small voltage or current coming from a plug to shift to large voltages or currents. Generally for normal circuits, small voltage is around 5V/6V/12V, 200mA and that of large one is around 110V/220V,16A as installed in routine use appliances in the households. It is an electronic component which works as a censor. By this it means that it turns the circuit on or off, whenever the power supply comes or goes, whatever the case may be. To name a few, it is extensively used in UPS systems in computers, inverters, car circuits, refrigerators, air conditioners etc.. It is responsible for the use of automatic power supply in case of power cut.

Protective Relay

Now when we talk about electrical appliances there are many categories, depending upon their usage, utility and the type of industry or manufacturing they are being used into and so does their electrical circuits’ structure. These days digitization and automation is ruling the game everywhere. So is happening in the relays. Sometimes instead of a single coil as used in normal relays there are multiple coils used to protect the circuits from getting overloaded. These functions are performed by the digital instruments called "protective relays".

Prominent features:

- These smart protective relays come with micro processors that wipe out wasteful trips, isolate faults and breakers, protect the motors and also provide information to manage systems effectively.

- These relays receive inputs, measure them with set points and then flow the output. Inputs may vary from current, voltage, resistance, or temperature.

- Outputs include visual feedback by way of indicator lights and/or an alphanumeric display, alarms, communications, control warnings, and switching power off and on.

Protective Relay Testing

For matters and systems involving electricity, it is very important to install protection systems for the safe and reliable operation for modern day electrical power sets. They help to maintain the safety in day-to-day working and handling of electrical equipments and also safeguard the assets from damage. In order to assure consistency and smooth flow of operation, protective relays and re-closer controls must be tested throughout their life-cycle, from their development in the beginning to periodical maintenance in the course of operation.

Purpose of protective relay testing

To isolate the high power circuit from low power logic circuit, relays are used to provide a low power signal so as to protect the low power circuit.

Supplemented by a coil, a pole terminal and a set of contacts (also called pins), relay provides a small electromagnetic coil for the logic circuit to control, and when the coil is flowing with energy; it ends up in a high power capacity magnetized switch that turns on the high power circuit.

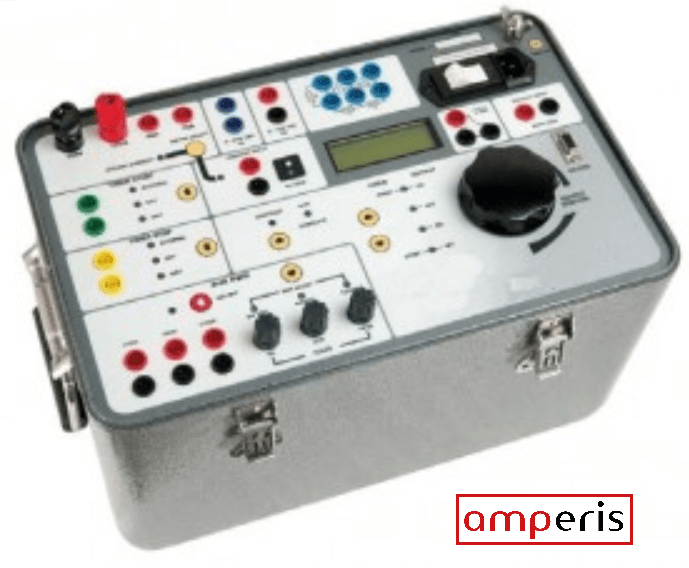

Amperis Relay testing ARFD 200

The ARFD-200 is a portable relay test power set that actively conducts the verification testing of electromechanical, electronic, and microprocessor based protective relays in their operating installations.

The ARFD-200 is a rugged test set suitable for testing a varying range of protection relays put to work in both inside and outside the work stations.

The unit’s sophisticated design and censor-like control panel structure renders it useful for intruders who have little or no training.

MAIN FEATURES:

Built-in Digital Timer- This smart and truly innovative feature on ARFD-200 functions independent start and stop trigger inputs. It also measures the time between event transitions and displays the elapsed time in both mili-seconds and cycles.

Built-in Power Resistors-The ARFD-200 accomodates built-in power resistors for fine current adjustment.

More protective relay testing:

3-Phase Relay testing AK-6. INFO

3-Phase Relay testing AK-10. INFO

3-Phase Relay testing AK-30. INFO

Primary Current Injection Source APCI-600. INFO